- Products

- Services

- Markets

- About

-

English US

English US

English US

English US

High pressure steam generation requires the removal of all dissolved solids. This can be accomplished with two bed (cation-anion) units or a mixed bed deionizer. It is common practice today to pretreat with reverse osmosis and then deionize with ion exchange.

High pressure steam generation requires the removal of all dissolved solids. This can be accomplished with two bed (cation-anion) units or a mixed bed deionizer. It is common practice today to pretreat with reverse osmosis and then deionize with ion exchange.

| Media Sub Category |

Strong Acid Cation |

| Polymer Matrix |

Styrenic Gel |

| Ionic Form |

Hydrogen |

| Applications: | |

|

- Demineralization |

|

| Media Sub Category |

Strong Acid Cation |

| Polymer Matrix |

Styrenic Gel |

| Ionic Form |

Hydrogen |

| Applications: | |

|

- Demineralization |

|

| Media Sub Category |

Strong Base Anion |

| Polymer Matrix |

Styrenic Gel |

| Ionic Form |

Hydroxide |

| Applications: | |

|

- Demineralization |

|

| Media Sub Category |

Strong Base Anion |

| Polymer Matrix |

Styrenic Porous Gel |

| Ionic Form |

Hydroxide |

| Applications: | |

|

- Demineralization |

|

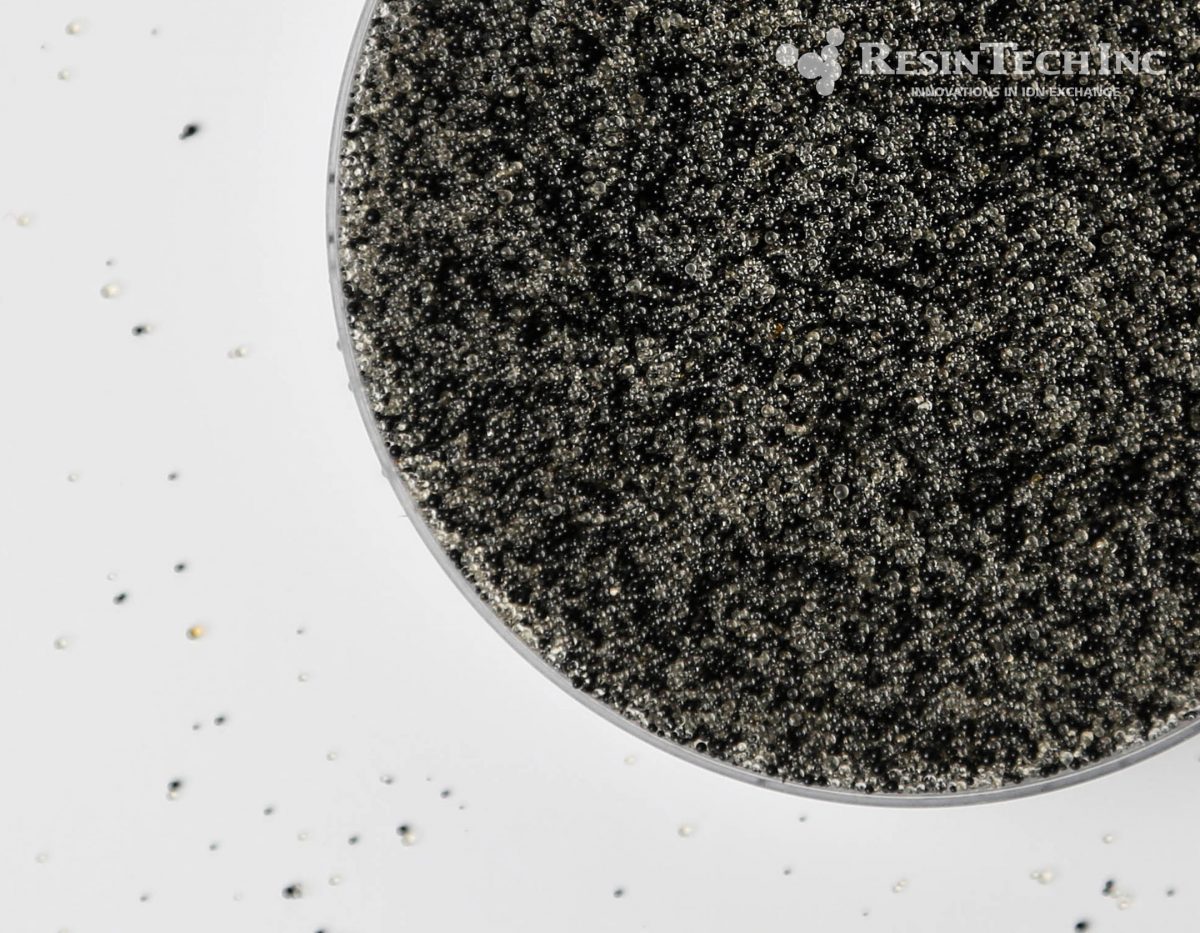

| Media Sub Category |

Mixed Bed |

| Polymer Matrix |

Styrenic Gel |

| Ionic Form |

Hydrogen & Hydroxide |

| Applications: | |

|

- Portable Exchange Deionization (PEDI) |

|

| Media Sub Category |

Mixed Bed |

| Polymer Matrix |

Styrenic Gel |

| Ionic Form |

Hydrogen & Hydroxide |

| Applications: | |

|

- Portable Exchange Deionization (PEDI) |

|

Need a little help deciding what to do next?

Reach out to us using the link below.

Tel: 856-768-9600

Fax: 856-768-9601

©2024 ResinTech, Inc.